OED is a company that has been focusing on customized carbide tools

for over 25 years, and we have produced over 3000+ special carbide

tools as per customer drawings.

From raw sintered products to finished ground parts as per your

drawings, we can provide the products you need. Our company is

famous for researching and developing special carbide tools. The

qualified products and reliable services can always satisfy our

customers, whether a simple plate or precision parts.

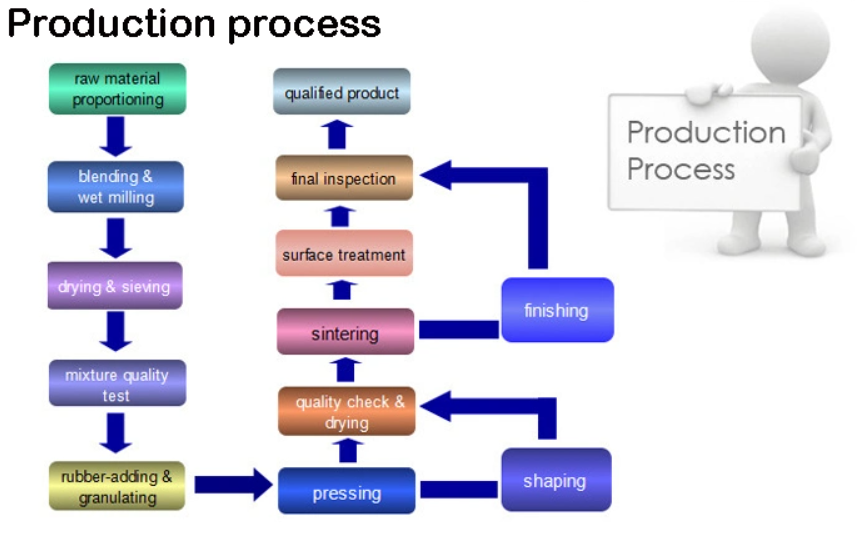

Our experienced engineers and skilled workers control the quality

strictly throughout all processes, from carbide powder to grinding

and packing. A qualified product is a key to satisfying customers,

and it will also help our partners to win more market.

Our main products are as follows:

Tungsten carbide tools for metalworking:

Circular knives

Curving tools

Milling tools

Punching tools

Scraps tools

Shear blades

Carbide rollers

Engraving tools

Bending tools

Forming tools

Tungsten carbide tools for woodworking

Carbide tips for saw blades

Carbide planer knives

Carbide strips/bevel strips

Circular cutting tools

Tungsten carbide mold parts

EDM Carbide plates/blocks for mold

Carbide punching pin

Carbide precision mold

Forming tools

Tungsten carbide wear parts

Bushes

Guide rollers for steel

Seal rings

Valve parts, such as balls, seats, cage

Thread nozzles

Sector plates

Regular carbide plates/strips/rods

Unground/Ground solid carbide rods

Straight coolant hole rods

Helical coolant holes rods

Cut-To-Length finished ground rods

Strips for woodworking